Filament Properties and Settings

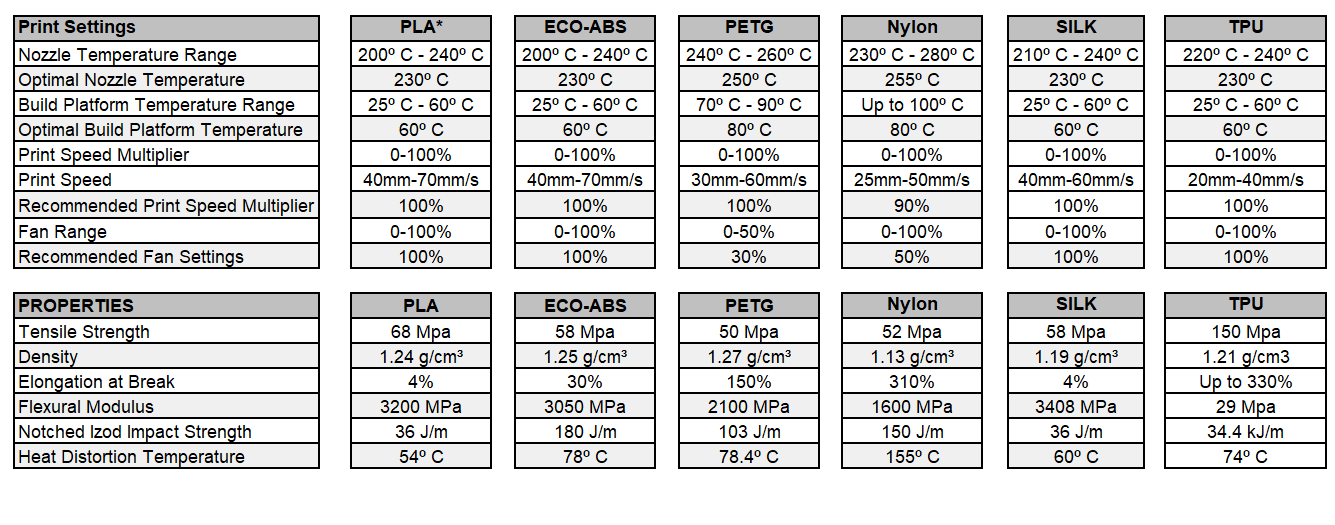

The material choice can make all the difference in your application whether your printing a part for visualization, making a functional prototype, or printing in the classroom. The right material choice can open up doors and enable accurate, functional prints. Use the information found on this page to determine what Dremel material is right for your next job.

* Regular PLA and Matte finish